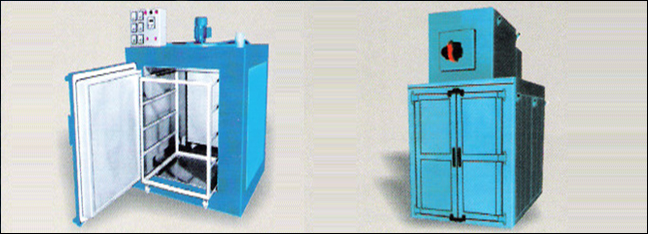

Crescent Ovens are designed to consume low power/Fuel with a uniform temperature throughout the Oven. Various safety features like Blower/Heat Source interlock, Pressure release mechanisms and Auto Shut-offs are provided to make these ovens fully safe. Crescent ovens can be heated by :

Crescent Ovens are designed to consume low power/Fuel with a uniform temperature throughout the Oven. Various safety features like Blower/Heat Source interlock, Pressure release mechanisms and Auto Shut-offs are provided to make these ovens fully safe. Crescent ovens can be heated by :

- Electric Heaters – Normally for Small Batch Type Applications.

- Oil Fired – HSD/LDO- With air to Air Heat Exchangers and Thermal Oil Heating.

- Gas Fired- CNG / PNG/ LPG /Propane – Normally used for large ovens . The Gas fired ovens can be

a) Direct Fired

b) In-Direct Fired.

- IR Heated – normally used for Plastic/ABS curing in a Tunnel type Oven.

STANDARD BATCH – PRODUCTION MODELS

| CEO – 445 |

4 X 4 X 5 |

15 KW |

1 HP |

| CEO – 446 |

4 X 4 X 6 |

21 KW |

2 HP |

| CEO -- 456 |

4 X 5 X 6 |

24 kw |

2 HP |

Diesel/Gas fired curing oven

Crescent Diesel / Gas Fired Ovens are designed in such a way so as to consume low Fuels with a uniform temperature in curing ovens. Our CURING OVENS are specially built and designed for Powder Coating and Liquid Paintings.

Crescent Diesel / Gas Fired Ovens are designed in such a way so as to consume low Fuels with a uniform temperature in curing ovens. Our CURING OVENS are specially built and designed for Powder Coating and Liquid Paintings.

Diesel / gas burner are fired in the Heat Exchanger

Cabins. A high efficiency Hot air circulation fan transfers the Heat from HE Cabin to the Heating Area

through Air Distribution Ducts giving uniform Temperatures inside the Ovens. These ovens can be Provided

with Ground rails and Trolleys for easy material

movements and Door openings can be Provided on One/Both sides of the Oven.

STANDARD BATCH – PRODUCTION MODELS

| CDO – 456 |

4 X 5 X6 |

HSD/LPG |

2 HP |

| CDO – 457 |

4 X 5 X7 |

HSD/LPG |

3 HP |

| CDO -458 |

4X5X8 |

HSD/LPG |

3 HP |

| CDO- 558 |

5X5X8 |

HSD/LPG |

3 HP |